|

产品中心 产品中心 |

|

|

| LQRY型导热油泵 |

|

一、产品概述:

LQRY系列热油泵,在我国载热体加热系统中得到广泛的使用,已经进入石油、化工、橡胶、塑料、制药、纺织、印染、筑路、食品等各个工业领域,主要用于输送不含固体颗粒的弱腐性高温液体,使用温度≤370℃,是一种理想的热油循环泵。

二、型号说明:

|

型 号 |

流量

(m3/h) |

扬程

(m) |

转速

(r/min) |

功率 KW |

效率

(%) |

气蚀余量

NPSH(m) |

|

轴功率 |

配用功率 |

|

|

4.5 |

15 |

2825 |

0.45 |

0.75 |

40 |

0.8 |

|

|

8 |

22 |

2840 |

1.0 |

1.5 |

42 |

1.6 |

|

|

10 |

25 |

2840 |

1.5 |

2.2 |

42 |

1.8 |

|

|

24 |

18 |

2890 |

3.1 |

4 |

46 |

1.8 |

|

|

12.5 |

32 |

2890 |

3.2 |

4 |

45 |

2.5 |

|

|

12.5 |

25 |

2880 |

2.5 |

3 |

45 |

2.2 |

|

|

50 |

16 |

2900 |

4.2 |

5.5 |

52 |

2.8 |

|

|

32 |

32 |

2900 |

4.5 |

5.5 |

52 |

2.7 |

|

|

40 |

25 |

2900 |

4.5 |

5.5 |

52 |

2.7 |

|

|

18 |

40 |

2890 |

4.5 |

5.5 |

52 |

2.8 |

|

|

25 |

50 |

2900 |

6.7 |

7.5 |

63 |

3.1 |

|

|

40 |

40 |

2900 |

6.7 |

7.5 |

63 |

3.1 |

|

|

60 |

20 |

2900 |

6.7 |

7.5 |

63 |

3.1 |

|

|

60 |

38 |

2930 |

9.2 |

11 |

68 |

3.9 |

|

|

80 |

40 |

2930 |

12.5 |

15 |

70 |

3.5 |

|

|

90 |

45 |

2930 |

15.7 |

18.5 |

70 |

3.6 |

|

|

58 |

50 |

2930 |

12.5 |

15 |

68 |

3.5 |

|

|

58 |

60 |

2930 |

15.5 |

18.5 |

62 |

3.5 |

|

|

100 |

55 |

2940 |

19.5 |

22 |

70 |

3.6 |

|

|

100 |

70 |

2950 |

25.5 |

30 |

69.8 |

4.1 |

|

|

100 |

80 |

2950 |

32.5 |

37 |

67 |

3.6 |

|

|

155 |

30 |

2940 |

20 |

22 |

72 |

3.6 |

|

|

160 |

45 |

2950 |

25.5 |

37 |

75.2 |

3.6 |

|

|

160 |

60 |

2970 |

35.5 |

45 |

74.2 |

5 |

|

|

300 |

55 |

2970 |

61 |

75 |

74 |

7.5 |

|

|

200 |

60 |

2970 |

42.8 |

55 |

76.4 |

6 |

|

|

300 |

70 |

2970 |

75.3 |

90 |

78.2 |

8 |

|

|

200 |

80 |

2970 |

59 |

75 |

74 |

6 |

|

|

260 |

70 |

2970 |

64.3 |

75 |

77.1 |

6.8 |

|

|

300 |

70 |

2970 |

75.3 |

90 |

78.2 |

8 |

|

|

260 |

85 |

2970 |

75 |

90 |

76 |

6.8 |

|

|

350 |

60 |

2970 |

75.2 |

90 |

76 |

8.6 |

|

|

400 |

50 |

2970 |

72 |

90 |

76 |

9.8 |

|

|

340 |

76 |

2970 |

89.5 |

110 |

78.6 |

8.5 |

|

|

400 |

60 |

2970 |

88 |

110 |

74 |

9.8 |

|

|

400 |

78 |

2970 |

106 |

132 |

80.6 |

9.8 |

|

|

370 |

85 |

2970 |

106 |

132 |

80 |

9.7 |

|

|

500 |

80 |

1480 |

136 |

160 |

76 |

5 |

|

|

600 |

80 |

1480 |

158 |

185 |

70 |

9 |

|

|

700 |

80 |

1480 |

190 |

220 |

81 |

14 |

|

|

400 |

50 |

1450 |

74 |

90 |

81 |

6.8 |

|

|

350 |

35 |

1450 |

61 |

75 |

80 |

6 |

|

|

720 |

30 |

1480 |

75 |

90 |

82 |

6.7 |

|

|

600 |

22 |

1480 |

69 |

90 |

80 |

6.5 |

|

|

800 |

20 |

1480 |

63 |

75 |

82 |

6.2 |

|

|

800 |

50 |

1480 |

190 |

185 |

83 |

6.2 |

|

|

1080 |

20 |

1480 |

92 |

110 |

78 |

6.0 |

|

|

1080 |

30 |

1480 |

112 |

132 |

76 |

6.0 |

|

|

1400 |

20 |

1480 |

145 |

160 |

80 |

6.0 |

结构原理

[1] [2] [3] [4] 下一页 |

| |

|

| |

|

|

|

|

ZX型卧式自吸离心泵

|

|

|

|

|

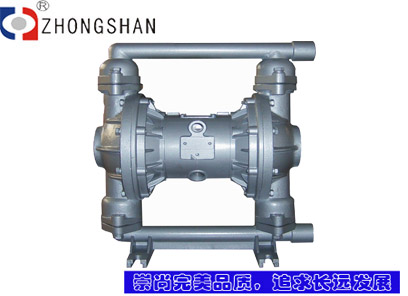

QBK气动双隔膜泵

|

|

|

|

|

CQ型磁力泵

|

|

|

|

|

IH型化工离心泵

|

|

|

|

|

ISG型管道离心泵

|

|

|

|

|

GDL型立式多级管道...

|

|

|

|

|

XBD-W型卧式单级...

|

|

|

|

|

ZW型自吸排污泵

|

|

|

|

|

CYZ型自吸离心油泵

|

|

|

|

|

ZB3A不锈钢转子泵

|

|

|

|

|

XBD系列全自动(变...

|

|

|

|

|

ISW卧式离心泵

|

|

|

|

|

|

|

|

|

|